Imagine this.

It’s laundry day.

Argh. You already hate it.

You load the machine with clothes.

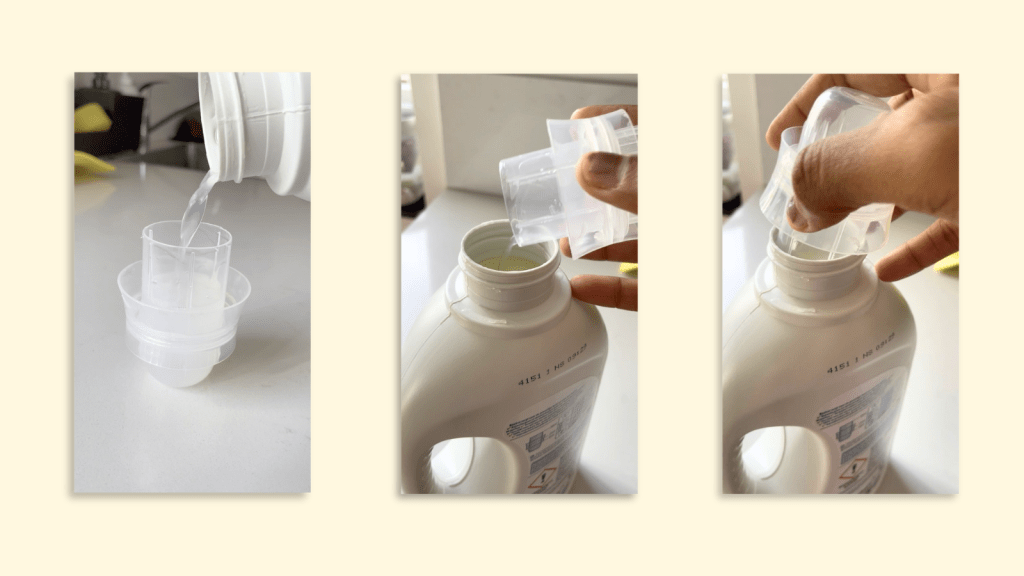

You unscrew the cap of the detergent bottle.

Pour the liquid.

Put the cap back on and Ahhh! Some detergent leaks out.

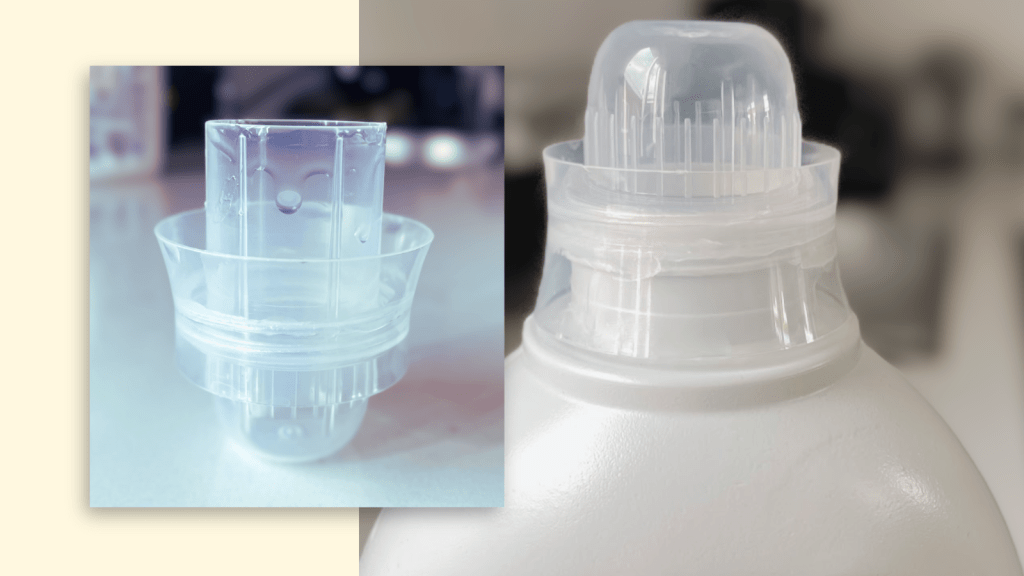

Now, take this Detergent Bottle Cap. Do you notice anything different?

It’s brilliant design.

It looks like a no-brainer and yet, you don’t see it everywhere.

It is not a ground breaking invention. Perhaps, no one even notices it. It makes an impact on your daily routine for just a fraction of second. To me, such designs are very impactful and thoughtful.

Designing a user-friendly bottle cap doesn’t directly increase revenue. Consumers don’t choose a brand solely for its superior cap design. Yet, companies invest time and effort to enhance these small details, making your life a little easier.

Until I read the book, “Design of Everyday things” by Don Norman, I never paid attention to the design of physical products. And until I became a product manager, I never really paid attention to the design of digital products either. But now, I think about product’s design all the time.

You might think, “How hard can this be? It’s just a bottle cap.

“While that’s mostly true, manufacturing physical goods is quite challenging. It involves long, tedious processes. You can’t simply change the design in your cool software and expect to release it in the next batch. Digital products, on the other hand, have that advantage of “rolling back” a release when it doesn’t meet expectations. With physical goods, you can’t simply roll back—there are dependencies from design to production phase.

Most manufacturing companies often outsource the production of certain parts. You design a part, create specifications for it, send it to your manufacturing unit. Now, this unit needs to support the design. If the manufacturer does not have the right equipment, they have to procure it. It is not same as spinning up another server with a single line of code or one-click action to scale up your digital product. Of course, I am over simplifying here but you get the idea.

When you take into account all these factors, you suddenly realize it may not have been an easy task to push such a design into production, especially when most detergent bottles in the market come with a standard cap.

Of course, once it becomes a standard design, it makes waves, and production becomes much easier.

So if you cannot change design on the fly, how do you iterate? How does the team validate the design choice?

Interestingly, digital and physical products share similarities in this aspect. You don’t always need to go straight to production. Instead, you can test your concept by creating a prototype—a working model that illustrates the user’s experience. This prototype serves as a tool to validate both your design and concept.

There is a cool video on Youtube on how car companies use clay modeling to experiment with design concepts.

Digital products also have prototypes. Check this prototype from Figma Community member. You can interact with a mobile app design without involving the software developers.

But, I digress.

For now, my detergent bottle has impressed me. It solves a tiny problem in my life and I derive immense satisfaction from it. Their core product is already good but design like this makes me go “Aha😊.” That’s the moment you want to have from your customers.

Leave a comment